plastic injection mould and plastic blow mould (include stretch blow mould and extrusion blow mould)

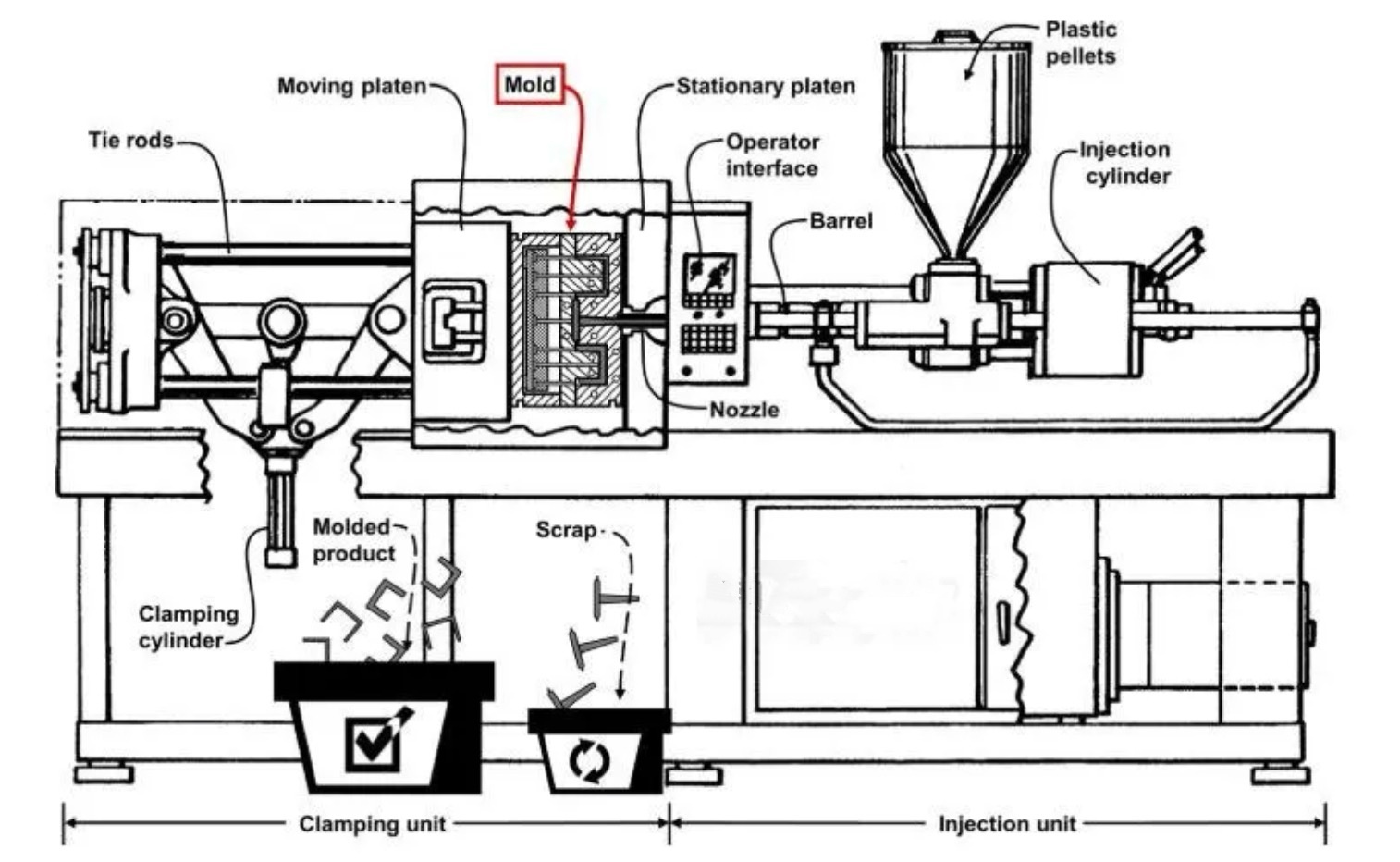

The plastic injection mould is inserted and clamped between a stationary and moving platen. The mold typically is connected and moves with the machine platens, so that the molded parts are formed within a closed mold. And after which the mold is opened the molded parts can be removed. Most injection moulding processes generally include plastication, injection, packing, cooling, and ejection stages. However different plastic part mould each stages parameters are different. Even same mold put into different tonnage injection machine, the parameter will be slight different. Therefor the injection molding operation should be accordingly actual status.

The plastic injection mould is inserted and clamped between a stationary and moving platen. The mold typically is connected and moves with the machine platens, so that the molded parts are formed within a closed mold. And after which the mold is opened the molded parts can be removed. Most injection moulding processes generally include plastication, injection, packing, cooling, and ejection stages. However different plastic part mould each stages parameters are different. Even same mold put into different tonnage injection machine, the parameter will be slight different. Therefor the injection molding operation should be accordingly actual status.

Normally include two plate and three plate mould. But when need to design mould with two plates and when three plate, depends on the plastic parts detail design.

1. restriction of the feed system route to the parting plane;

2. limited gating options from the feed system into the mold cavity or cavities;

3. restriction on the tight spacing of cavities;

4. additional forces imposed on the mold by the melt flowing through (and being pressurized within) the feed system;

5. increased material waste incurred by the solidification of the melt in the feed system;

6. and increased cycle time related to the plastication and cooling of the melt in the feed system.

Two plate mould filling gate can be designed within three types: side gate, submarine gate and horn gate. Side gate design, runner connected with part after ejected out from mould. While submarine gate, runner sperated with part automatically. But not all the parts can be designed with submarine gate. For example, part height too low, no enough space for submarine gate. This type is because of the part design. The second type is because of plastic material. Part material crisp. As there is an angle on submarine gate filling runner, so when part material is srap material, the filling runner will be broken inside the submarine filling runner. For the horn gate, similar with submarine gate, but have stricter condition.

For molding applications requiring high production quantities often do not use two-plate mold designs, but instead use mold designs that are more complex, yet provide for lower-cost production of the molded parts. Such designs include three-plate molds, hot runner molds, stack molds, and others. Three-plate molds and hot runner molds are the next most common types of injection molds.

Compares the different types of molds with respect to several performance measures. In general, hot runner molds are excellent with respect to molding cycle performance but poor with respect to initial investment, start-up, and on-going maintenance. By comparison, two-plate molds have lower costs but provide limited molding cycle productivity. The evaluation of three-plate molds in table warrants some further discussion. Specifically, three-plate molds do not provide as high a level of molding productivity compared to hot runner molds, and at the same time have higher costs than two-plate molds. For this reason, there has been a trend away from three-plate molds with the penetration of lower cost hot runner systems.

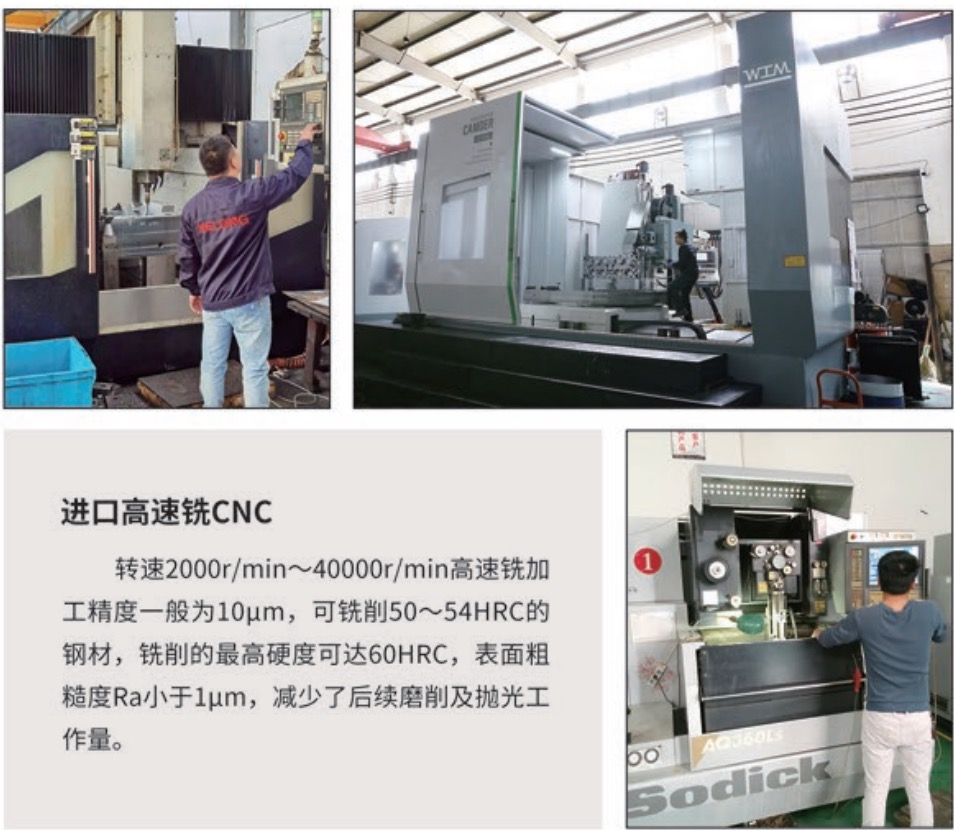

Our workshop

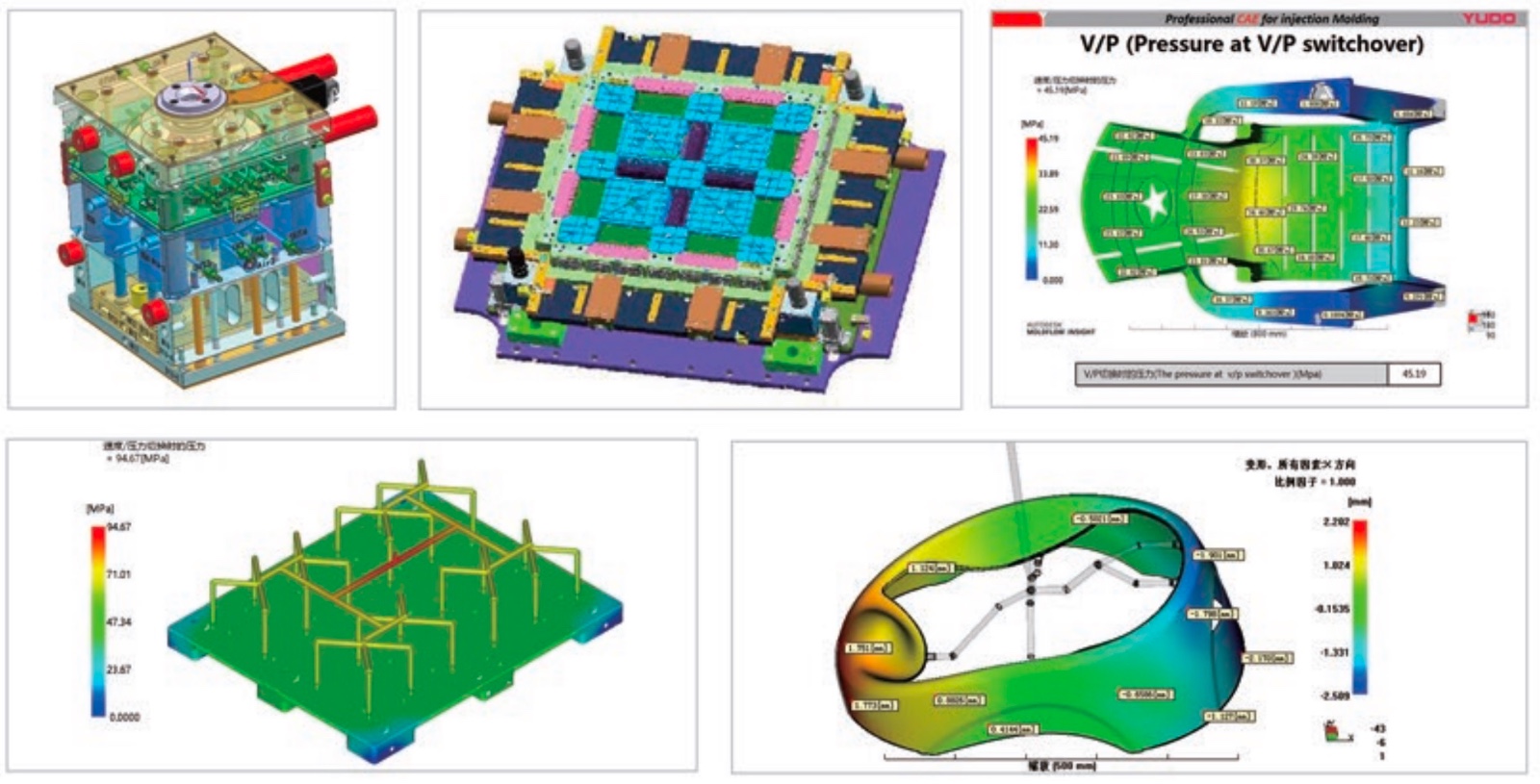

Moulds design

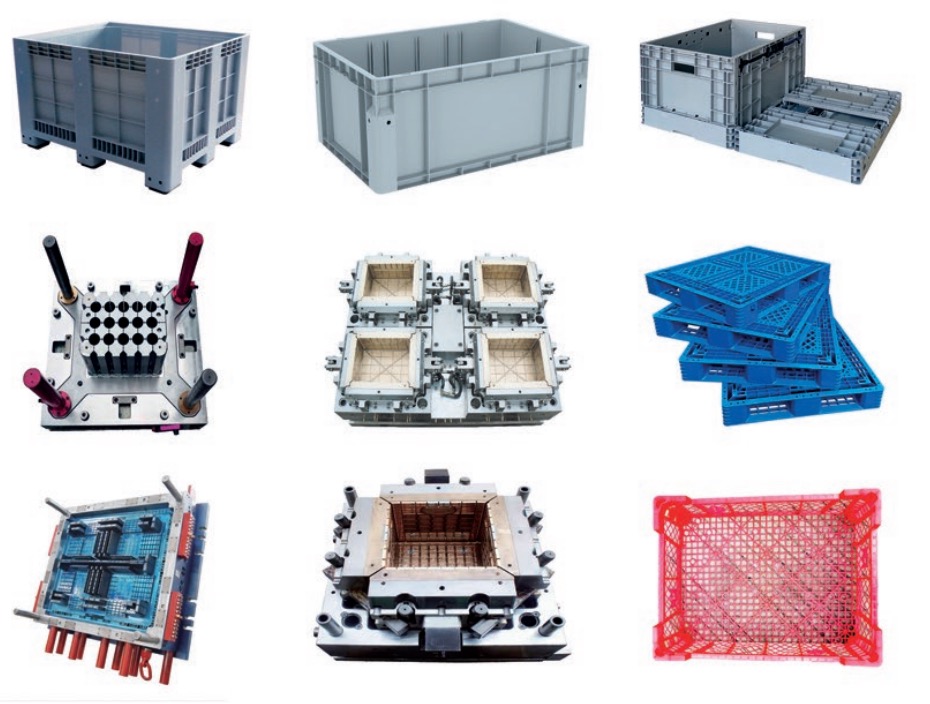

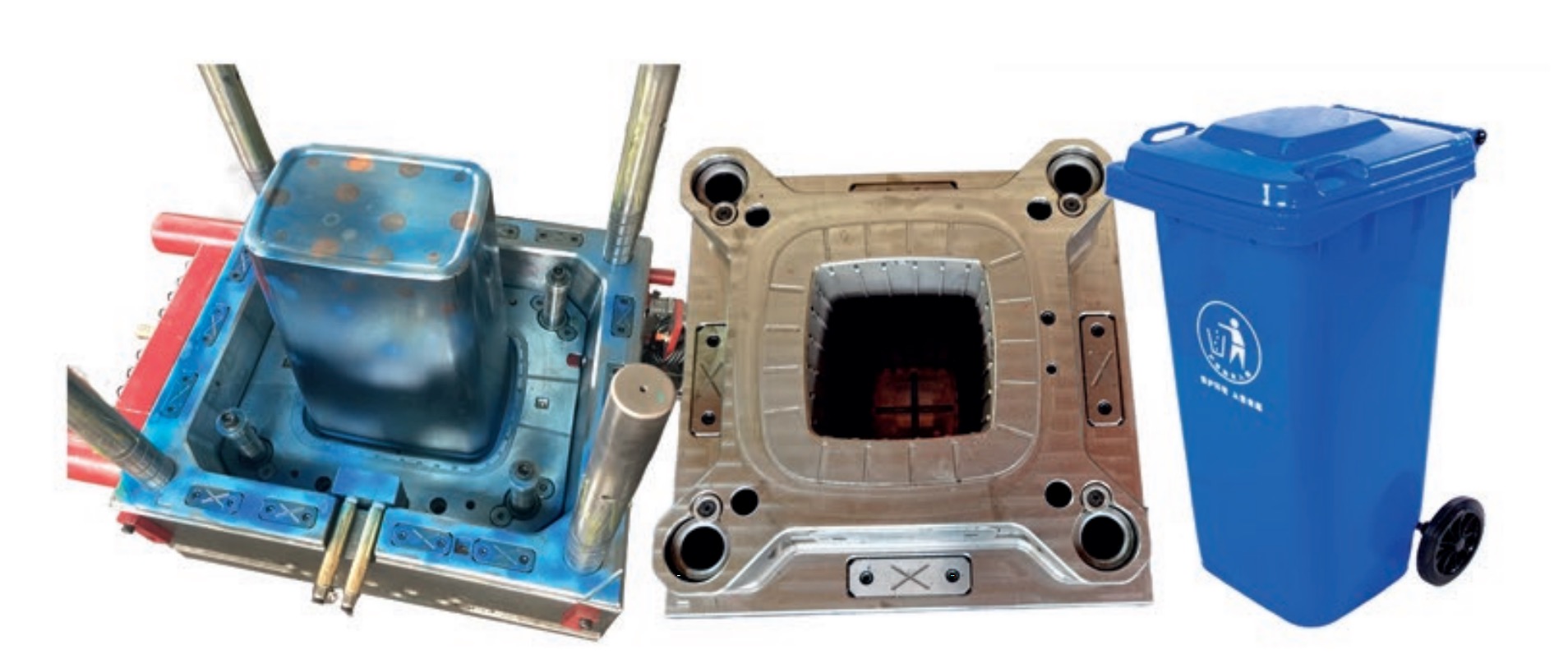

Our moulds show

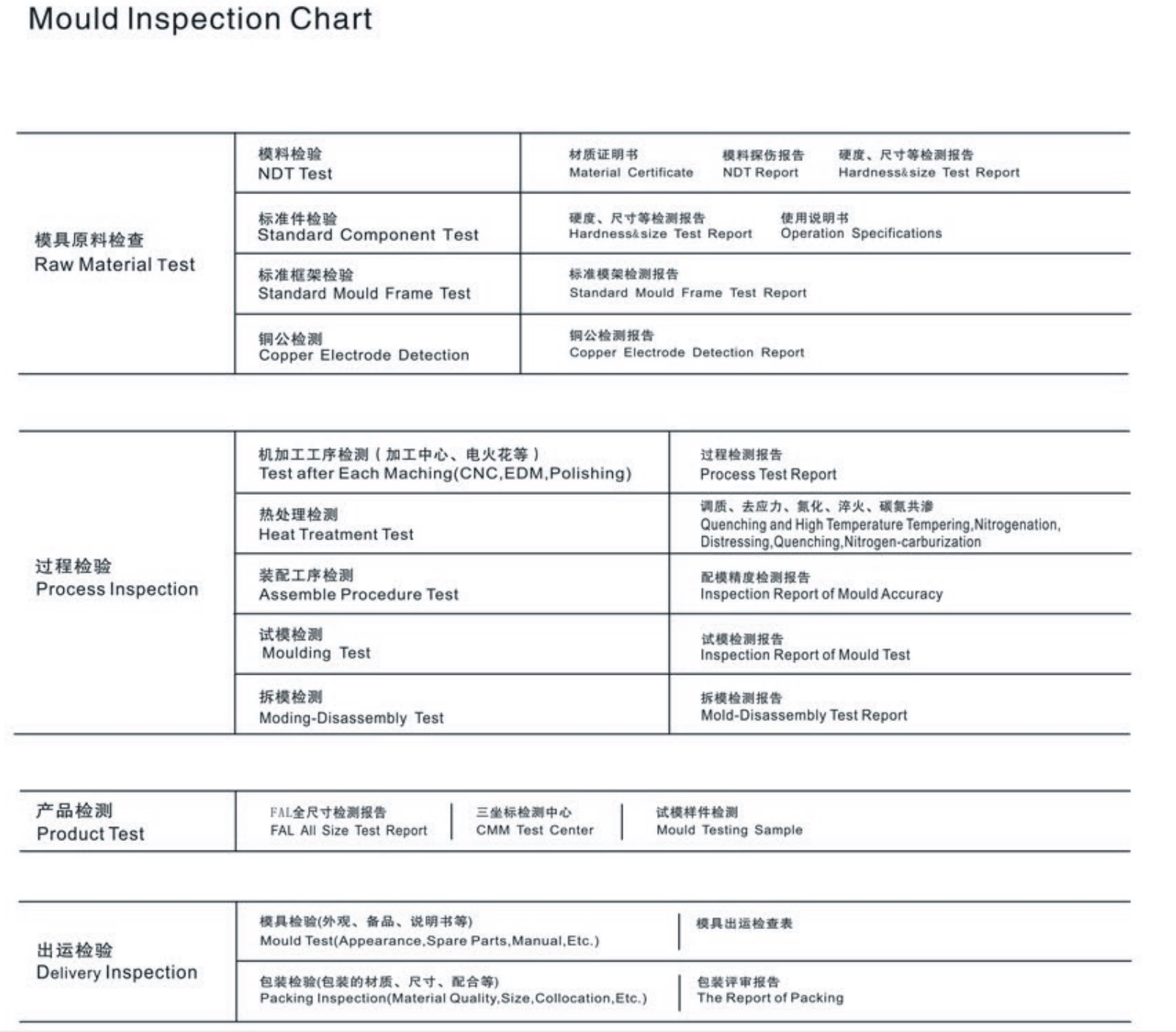

Our quality guaranteed inspection